The carboxymethyl cellulose, or CMC for short, is an ionic carboxymethyl cellulose of water-soluble cellulose ether. It can form high viscosity colloid, solution, adhesion, thickening, flow, emulsion dispersion, film forming and other characteristics. It has a good and easy and no cracking characteristics, construction industry-grade CMC for plaster, water-resistant putty, bonding gypsum, plaster seam, can significantly improve its water retention and bonding strength.

The carboxymethyl cellulose is a non-toxic and tasteless white or light yellow powder, which is free-flowing, stable in performance and soluble in water. Its aqueous solution is a neutral or alkaline transparent viscous liquid, soluble in other water-soluble adhesives and resins, insoluble in organic solvents such as ethanol. The PH is 7.0-9.0, the maximum moisture content is 10% , and the viscosity is 100-8000 mpa.s in 2% aqueous solution at 25 °C. Storage conditions should be kept cool and dry, avoid direct sunlight.

The carboxymethyl cellulose has many remarkable features. It has a good water-soluble, with common mixing equipment can be easily dissolved in hot and cold water. During winter construction, it shows good temperature resistance and salt resistance. And low ash, used in emulsion can increase viscosity, stability and dispersion are both good. In addition, excellent compatibility, with a variety of water-soluble glues, emulsifiers and resins perfect fusion.

In building materials, the carboxymethyl cellulose is a “Jack of all trades”In cement mortar, it is the guarantee of plasticity and water retention, for the excellent quality of mortar, eliminate cracks. In ceramic tile cement, carboxymethyl cellulose enhances the plasticity and water retention of the mortar used for pressing ceramic tiles, making them stronger and reducing the risk of falling off. In gypsum concrete slurry, it improves the water retention and processability, to ensure the stability and reliability of the structure. Both large-scale buildings and home decoration, carboxymethyl cellulose are unique performance to enhance the quality of building materials and construction results.

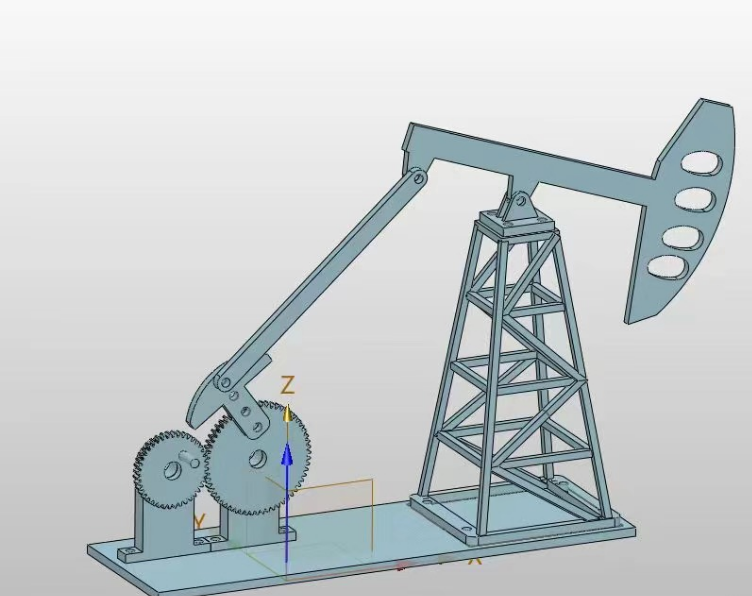

The carboxymethyl cellulose is also used in oil and gas drilling and well drilling. The carboxymethyl cellulose mud is stable, reducing water loss even at temperatures above 150 °C. it also gives the rig a low initial shear, allowing the mud to release trapped gases, at the same time, the debris was quickly dumped into the mud pit. The use of carboxymethyl cellulose has greatly improved the efficiency and quality of drilling operations.

The carboxymethyl cellulose in the joint cement can enhance the fluidity and water retention, making the joint more efficient and better results. In coatings, it is used as plasticizer of latex coatings, greatly improving the performance and fluidity of coatings and putty powder. Make coating daub even, putty powder construction convenient, wall effect more perfect. All in all, carboxymethyl cellulose has become an indispensable part of the construction and coating industry with its outstanding performance.