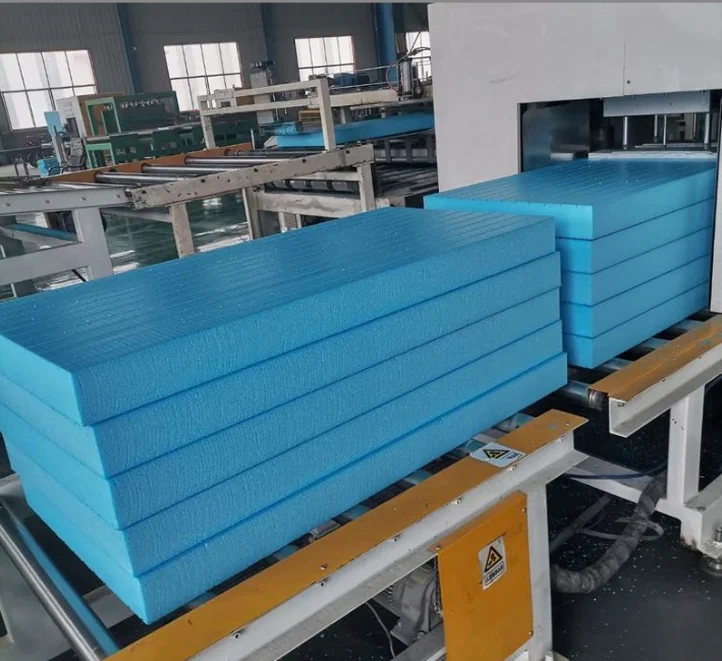

XPS foam board is a rigid foamed plastic board made of polystyrene resin as raw material plus other raw materials and polymers, mixed with heat and injected with a catalyst, and then extruded. Its scientific name is extruded polystyrene for heat insulation. Styrene foam plastic (XPS for short), XPS has a perfect closed-cell honeycomb structure, which makes the XPS board have extremely low water absorption (almost no water absorption), low thermal conductivity, high compression resistance, and aging resistance (normal Use almost no aging decomposition phenomenon).

|

Item |

Unit |

Size(mm) |

|

Length |

mm |

1800,1200 |

|

Width |

mm |

600, 900, 1200 |

|

Thickness |

mm |

20,25,30,40,50,60,70,80,90,100 |

|

Item |

Unit |

Performance |

Test Methods |

|

Compressive strength |

Kpa |

≥150 |

GB/T8813-1988 |

|

Water absorption rate soak in water for 96h |

%(W/W) |

<1.0 |

GB/T 8810-1988 |

|

Moisture permeability coefficient |

ng/(m.s.pa) |

«3.0 |

QB/T 2411-1998 |

|

Thermal Conductivity |

W/(m.k) |

«0.028 «0.030 |

GB/T 10294-1988 |

|

Dimensional stability |

% |

«1.5 |

GB/T 8811-1988 |

|

Oxygen Index |

|

»26 |

GB/T 8826-1988 |

1. Excellent thermal insulation

It has the characteristics of high thermal resistance, low linearity, and low expansion ratio. The closed cell rate of its structure has reached more than 99%, forming a vacuum layer, avoiding air flow and heat dissipation, and ensuring its long-lasting and stable thermal insulation performance. Compared with foamed polyurethane, it is 80% The closed cell rate is self-evident. Practice has proved that the 20mm thick XPS extruded insulation board has the same thermal insulation effect as 50mm thick expanded polystyrene and 120mm thick cement perlite. Therefore, this material is the best choice for building thermal insulation.

2. Excellent high-strength compression resistance

Due to the special structure of the XPS board, its compressive strength is extremely high and its impact resistance is extremely strong. According to different types and thicknesses of XPS, its compressive strength can reach more than 150-700Kpa, and it can bear the ground load of various systems. It is widely used in geothermal engineering, Highway, airport runway, square ground, large cold storage and car interior decoration and heat preservation and other fields.

3. Excellent water repellency and moisture resistance

Water absorption is an important parameter to measure insulation materials. After the thermal insulation material absorbs water, its thermal insulation performance decreases. Under low temperature conditions, the sucked water is easy to freeze, which destroys the structure of the thermal insulation material, thereby reducing the compression resistance and thermal insulation performance of the board. Since the molecular structure of polystyrene itself does not absorb water, the molecular structure of the board is stable and there are no gaps, which solves the problems of water leakage, penetration, frosting, and condensation of other materials.

4. Light texture, easy to use

The completely closed-cell foaming chemical structure and the honeycomb physical structure of the XPS board make it light and high-strength, easy to cut and transport, not easy to break, and easy to install.

5. Good stability and corrosion resistance

In long-term use, it will not age, decompose, or produce harmful substances. Its chemical properties are extremely stable. It will not be degraded by water absorption and corrosion, which will cause its performance to decline. It can still maintain its superior performance in high temperature environments. According to relevant information, the service life of XPS extruded plastic insulation board produced by major domestic manufacturers is about 60 years, and it can still maintain excellent performance, and it will not decompose or mildew, and there will be no volatilization of toxic substances.

6. Product environmental performance

The environmental protection performance of XPS board mainly depends on the foaming agent. At present, most domestic manufacturers use CO2 as the catalyst, but some manufacturers have been using Freon. The relevant national departments have tested that the chemical performance is stable, does not volatilize harmful substances, and is harmless to the human body. The use of environmentally friendly materials does not produce any industrial pollution. This product is an environment-friendly building material.